Torque Tension 600N Atutomatic Constant Tension Controller

Automatic Control A-600

Briefly

In many industrial such as paper, textiles, plastic film, wire,

printed matter, magnetic tape, metal strip wire, etc., the

rewinding and unwinding tension of the material is critical to the

quality of the product. Constant tension control is required for

this purpose. The automatic tension controller KDT-1-600 is an

automatic control system that realizes constant tension control.

Its function is mainly to achieve synchronization between the

rollers and continuously uniform control of rewinding and

unwinding. Automatic tension control system consists primarily of

an automatic tension controller, pressure sensor, magnetic powder

brake or clutch. It is suitable for high-precision and high-speed

tension control applications, and has the advantages of high

control precision and good real-time performance.

Parameters

Automatic tension controller

| Model | KDT-A-600 | KDT-A-1000 | KDT-B-600 | KDT-B-1000 |

| Measurement accuracy | 1 Newton | 1 Newton | 1 Newton | 1 Newton |

| Sampling speed | 100 milliseconds | 100 milliseconds | 100 milliseconds | 100 milliseconds |

| Output | 24V/0-4A | 24V/0-4A | 24V/0-4A | 24V/0-4A |

| Input | AC180-245V | AC180-245V | AC180-245V | AC180-245V |

| Size(L*W*D) | 245*155*120mm | 245*155*120mm | 245*155*120mm | 245*155*120mm |

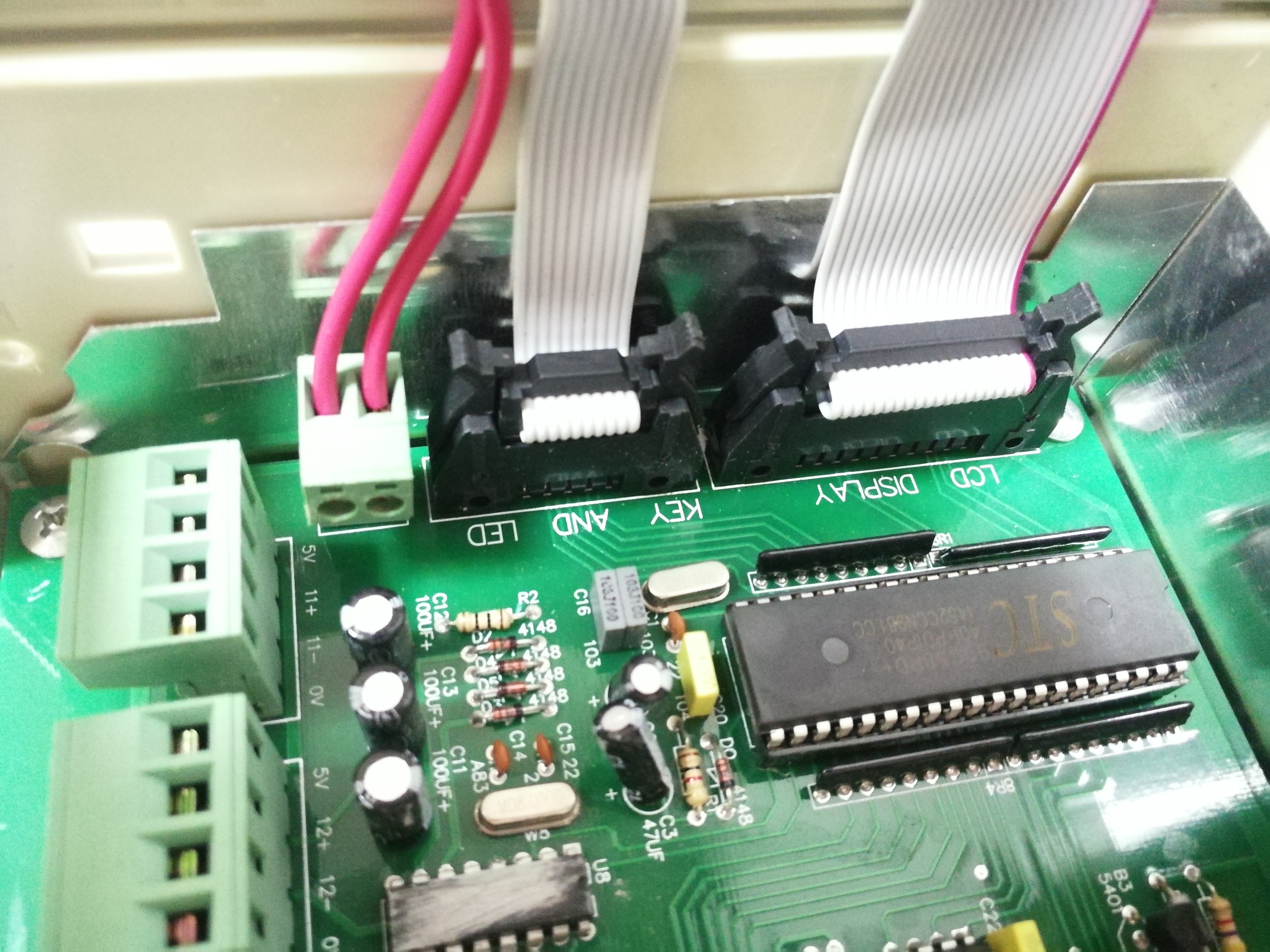

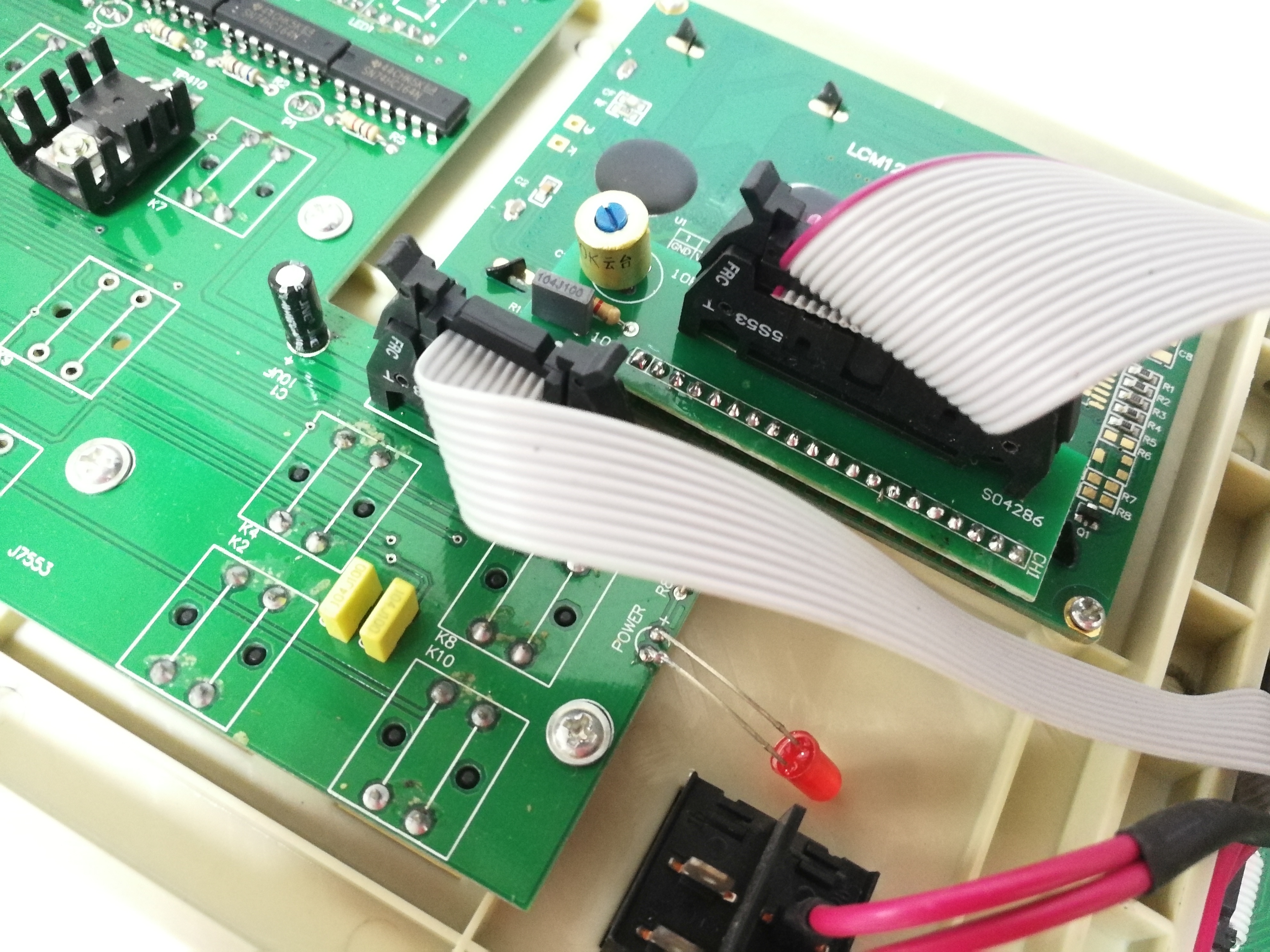

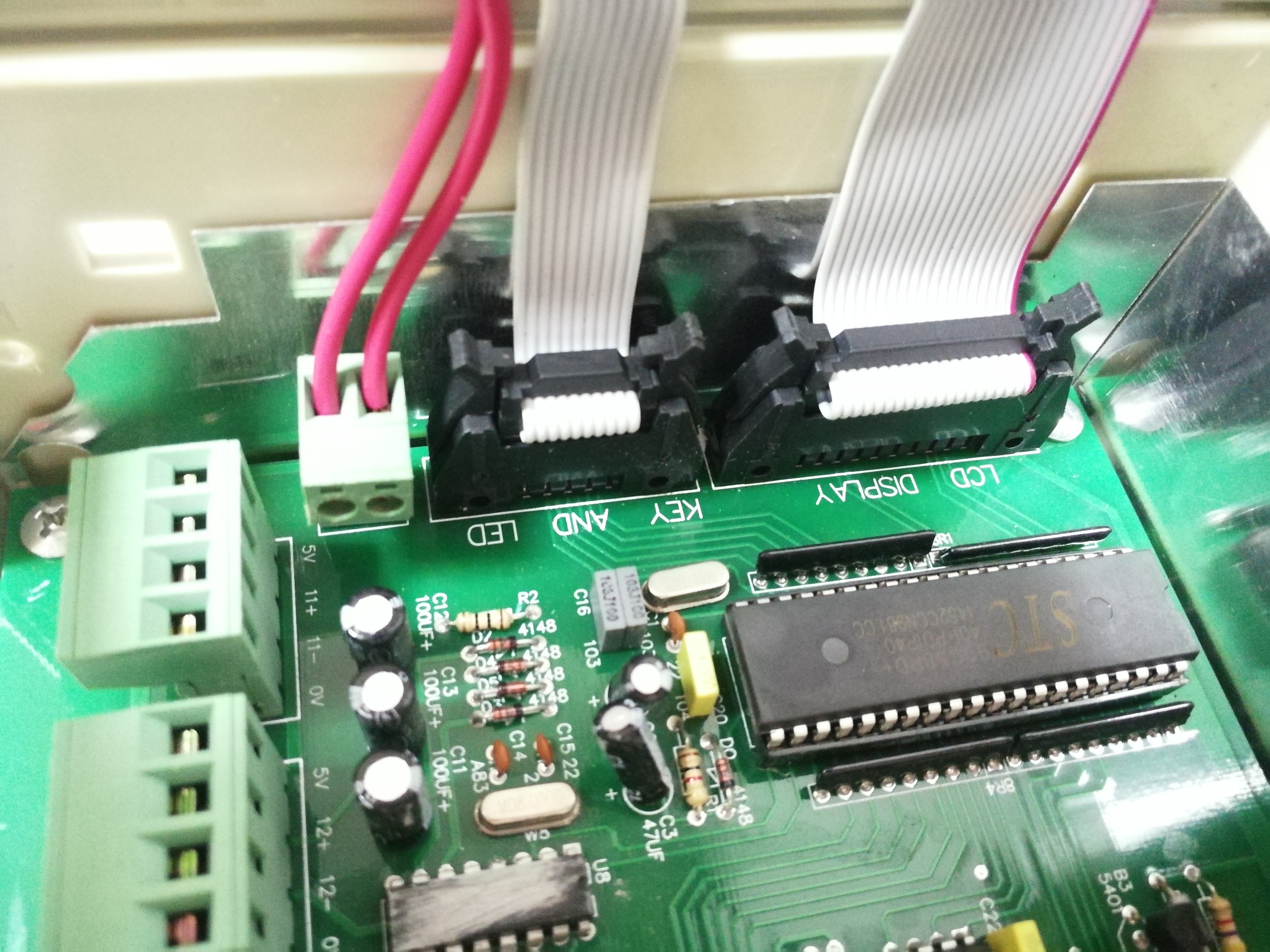

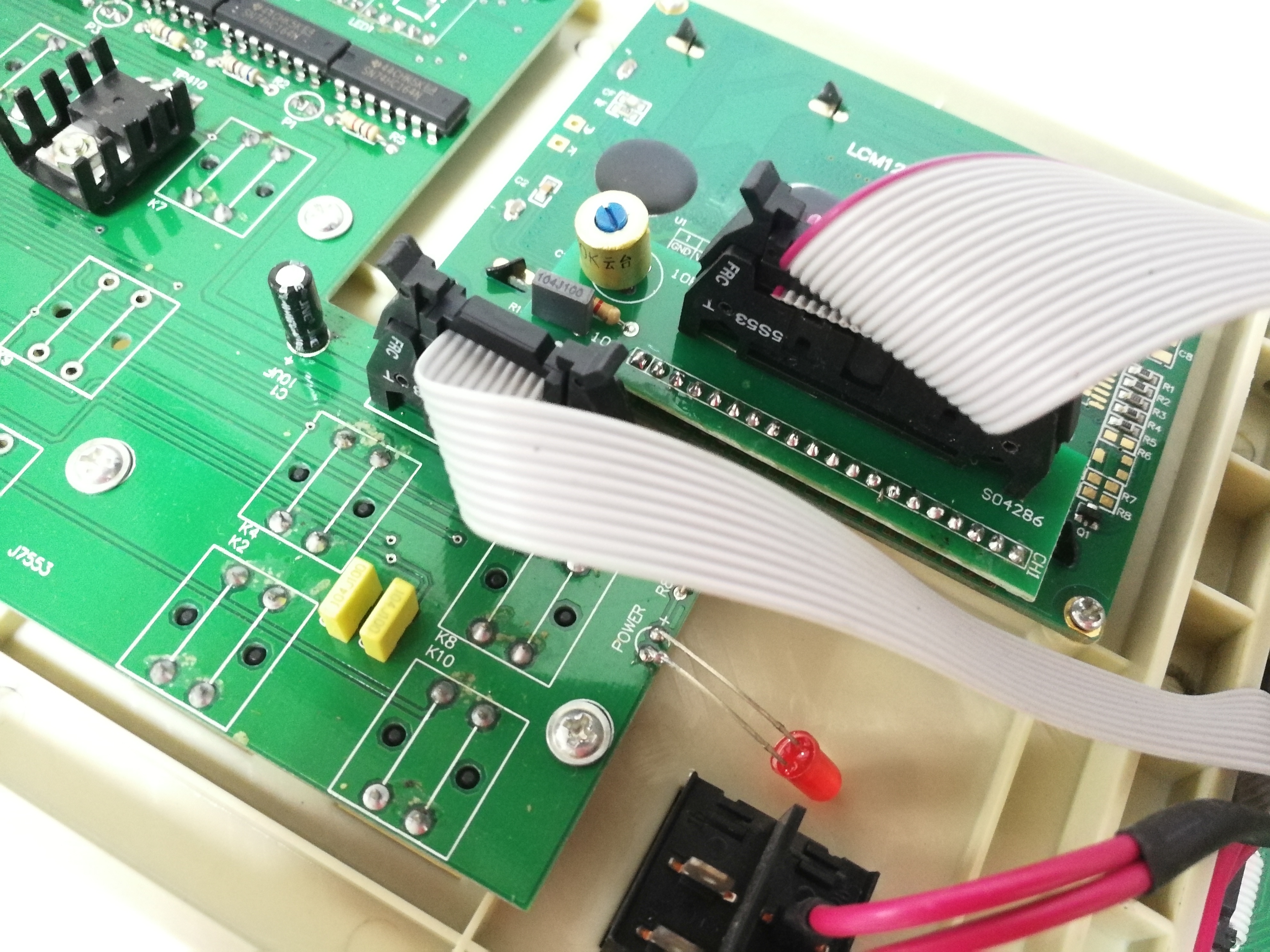

| Display | LCD display | LCD display | Digital display | Digital display |

| Loadcell | Rectangle | Rectangle | Rectangle | Rectangle |

| Maximum tension detective | 600N | 1000N | 600N | 1000N |

| Working tempreture | -25℃~+55℃ | -25℃~+55℃ | -25℃~+55℃ | -25℃~+55℃ |

| Working humidity | ≤85%(20℃±5℃) | ≤85%(20℃±5℃) | ≤85%(20℃±5℃) | ≤85%(20℃±5℃) |

Manual tension controller

| Model | ZL2A-5S | ZL3A-5S | ZL803F |

| Measurement accuracy | 1 Newton | 1 Newton | 1 Newton |

| Sampling speed | 100 milliseconds | 100 milliseconds | 100 milliseconds |

| Output | 24V/0-2A | 24V/0-3A | 24V/0-4A |

| Input | AC180-240V | AC180-240V | AC180-240V |

| Size(L*W*D) | 180*110*69mm | 180*110*69mm | 180*110*85mm |

| Working tempreture | -25℃~+55℃ | -25℃~+55℃ | -25℃~+55℃ |

| Working humidity | ≤85%(20℃±5℃) | ≤85%(20℃±5℃) | ≤85%(20℃±5℃) |

Features

1. Automatic unwind tension system deploys material tension

detection roller.

2. The device will support auto-stop operation when material

tension reaches the upper and lower limitation.

3. Unwinder device deploys automatic compensation tension control

device.

4. The rotation speed then pre-set tension maintain by the roller

when printing material rotate through the printing machine, no

matter what the size, width, material.

5. Tension sensors roller monitor the roller tension of the

material and amend any changes of the tension.

6. Maximum tension can up to 600N

Control mode

1. Manual panel control.

According to the winding unwinding situation, the manual knob

adjustment is manually performed to control the magnitude of the

exciting current to obtain the required tension.

2. External PLC control.

The PLC needs to be equipped with a 10V analog output module. With

the tension detector, automatic constant tension control can be

formed, or manual adjustment can be made through the touch screen.

3. External potentiometer control

The short wiring of +10V and ADJ needs to be removed, and the panel

knob must be twisted to the right.

Note: The magnetic powder brake and clutch wiring is not divided

into positive and negative poles.

Application

- Printing systems: conveyors and in-feeders

- Wood-working systems: saws, wood-working machine, laminators

- Testing systems: lab machines, durability testers, measuring

systems

- Food processing systems: meat cutting machines, cookie making

machines, canning machines, noodle making machines

Feeding process:

Torque motor output torque, connected to magnetic powder brake,

then the brake connects with the feeding shaft to feed the

material. Electric torque-motor controller control the torque

motor, tension controller control the magnetic powder brake,

resulting in uniform material feed and proper speed.

Rewinding process:

Torque motor output torque, connected to magnetic powder clutch,

then the brake connects with the rewinding shaft to collect the

material. Electric torque-motor controller control the torque

motor, tension controller control the magnetic powder clutch,

resulting in uniform material rewind, proper speed and roll tight.

Advantages

1. Display Chinese and English

2. Automatic and manual switching is simple and convenient

3. Tension detector wiring is simple and convenient

4. Convenient parameter settings

FAQ

1. When can I get the quotation?

We usually quoted within 24 hours after receiving your inquiry. If

you are very urgent to get the price, please call us or tell us in

your email, so that we can regard your inquiry priority.

2. How should I place the order?

Please let us know the model number based on our specs for powder

clutch, powder brake, air clutch, air brake, electromagnetic

clutch, electromagnetic brake and safety chucks. For air shaft and

roller, please show us your drawing, or let us know your request,

and then we will provide you drawing for confirmation.

3. What’s your MOQ basis?

Normally, we don’t have MOQ request, except the rollers.

4. What about the lead time for production?

Honestly, it depends on the order quantity and the type of our

products. For powder clutch, powder brake, tension controller, load

cell and edge position controller which is about 3-5 days. For

safety chucks, air shaft and roller which need about 15-30days.

5. What is the term of delivery?

We can arrange with EXW, FOB, CIF…etc. You can choose the most

convenient one or cost-effective way.